Indian Institute of Technology, Patna

RESEARCH

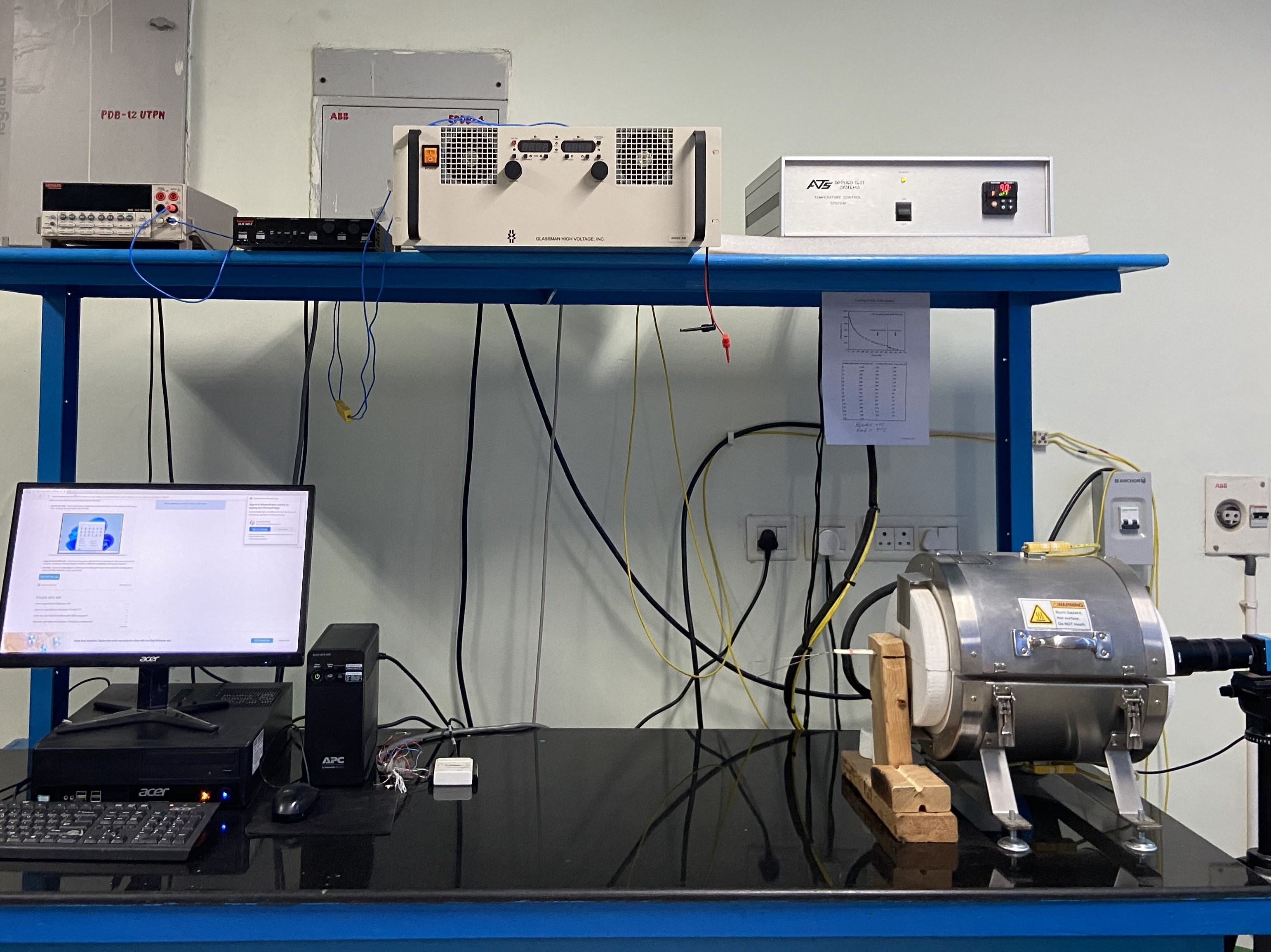

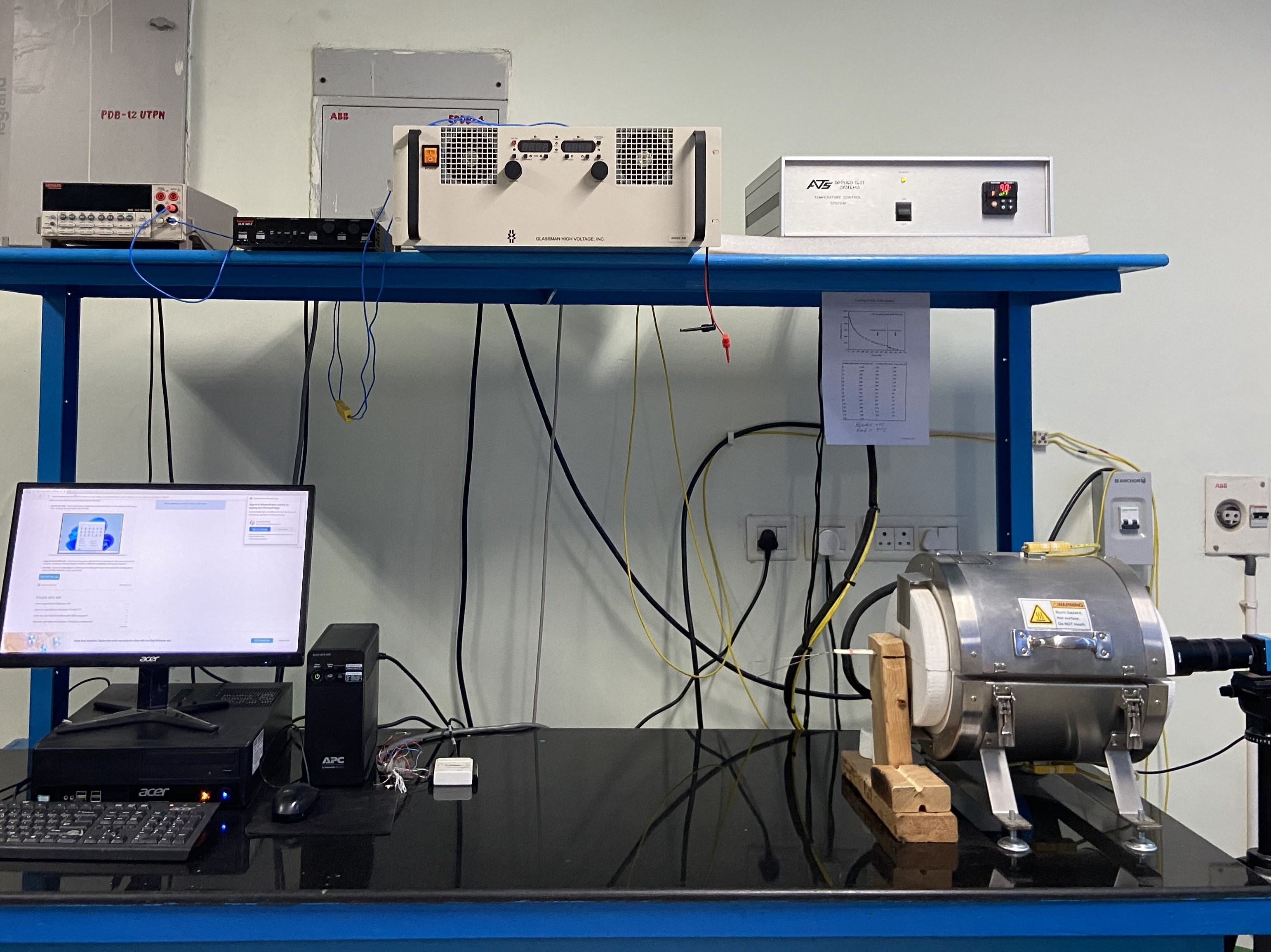

Our group focuses on flash sintering of ceramics. Flash sintering involves sintering of ceramic materials in few seconds at remarkably low furnace temperatures. This is achieved by applying electric field across the green bodies with a pair of electrodes. The unusually low processing temperatures and short sintering times has opened up a new era in ceramics manufacturing. The densification kinetics is so quick that no time is given for grain growth, and flash sintering give rise to 30% smaller grains compared to the conventionally sintered samples, hence, better mechanical properties. Flash sintering experiments are primarily characterized by a non-linear rise in the electrical conductivity of the ceramics. The otherwise insulting ceramics behaves like conductors in the state of flash. Our main aim is to understand the mechanism of flash sintering.

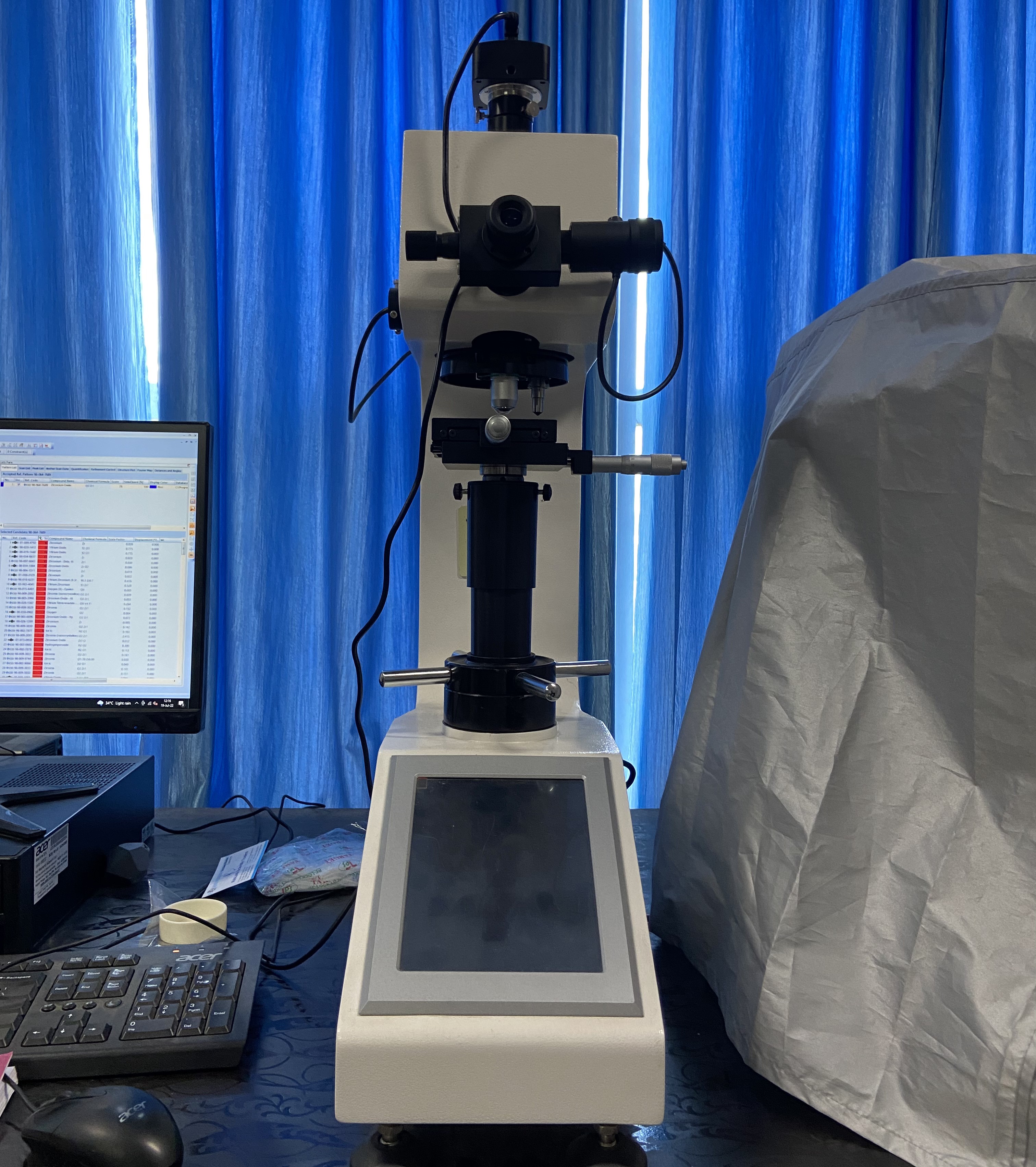

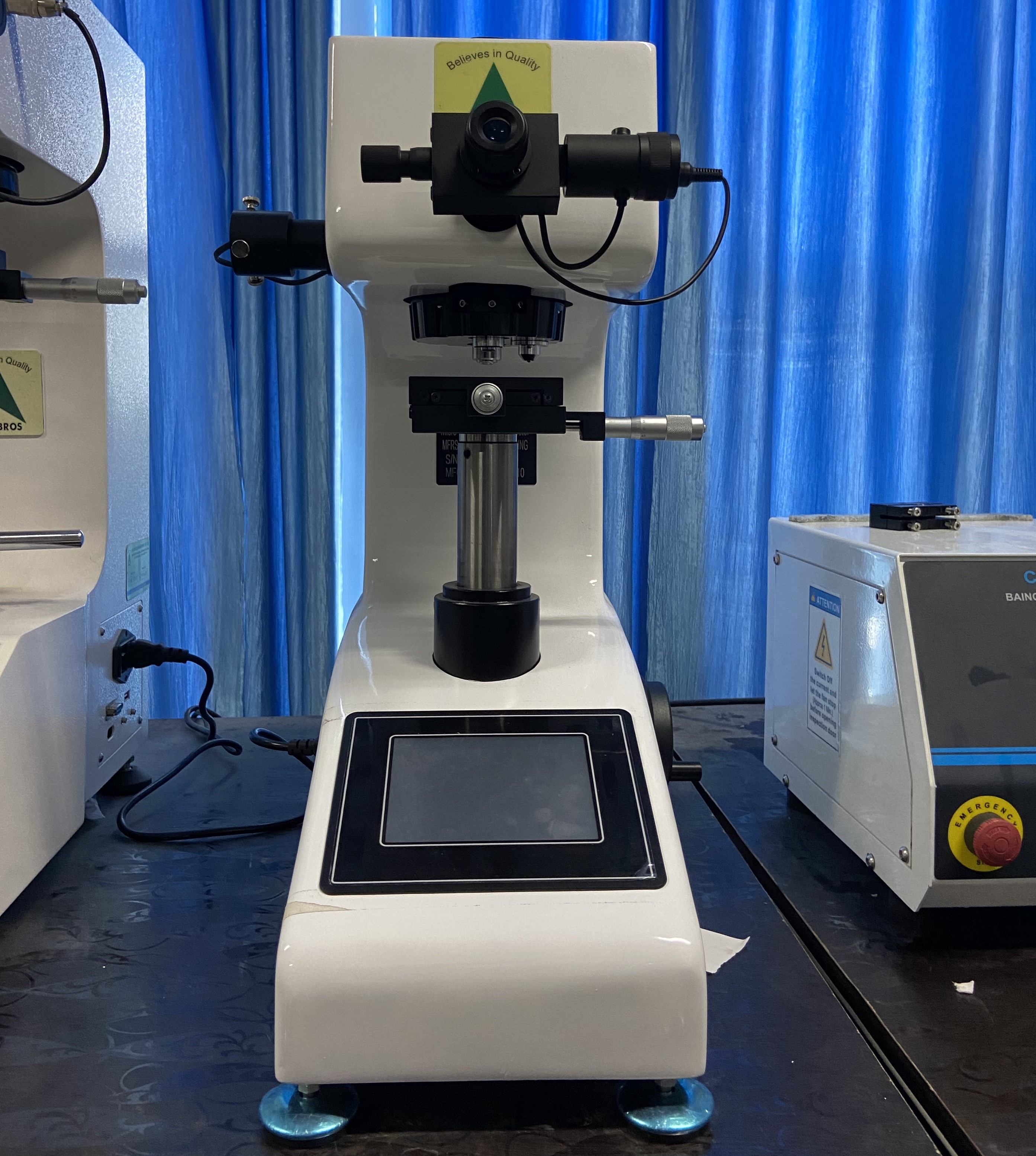

We not only use the technique of flash sintering for sintering, but also to synthesize new materials. We also perform the flash phenomena experiments on dense samples (single crystals and polycrystal) where there is no sintering effect, to understand the structural changes introduced inside the material during the flash phenomena. In addition to flash sintering, our group also works on friction surfacing, where we try to repair surface cracks on engineering components, so that the same component can be put to service once again. By this way we can enhance the service life of components and structures. Here we work on the concept of “repair over replace” We study the structure-property correlation in detail through diffraction and microscopy based techniques.

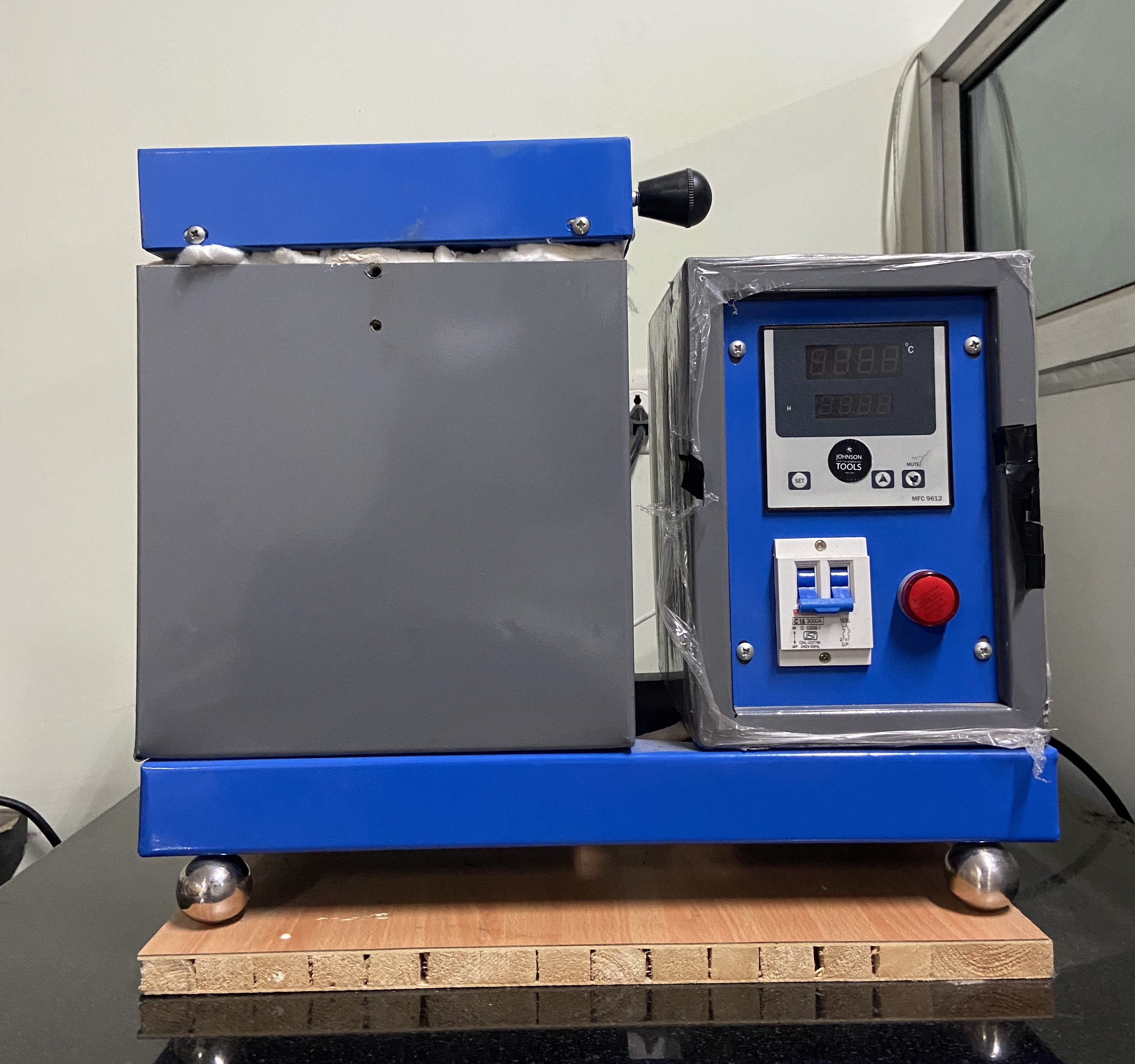

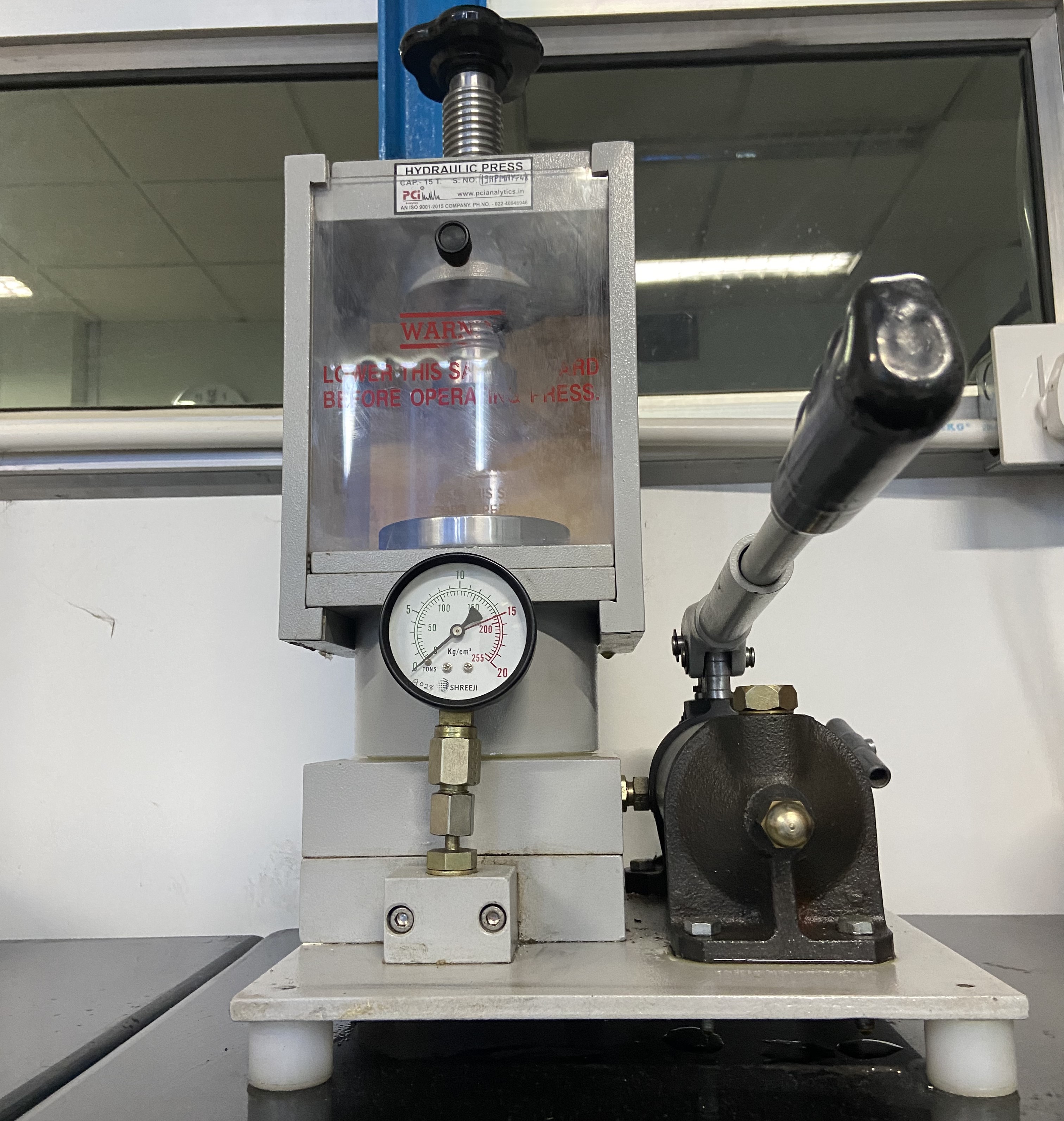

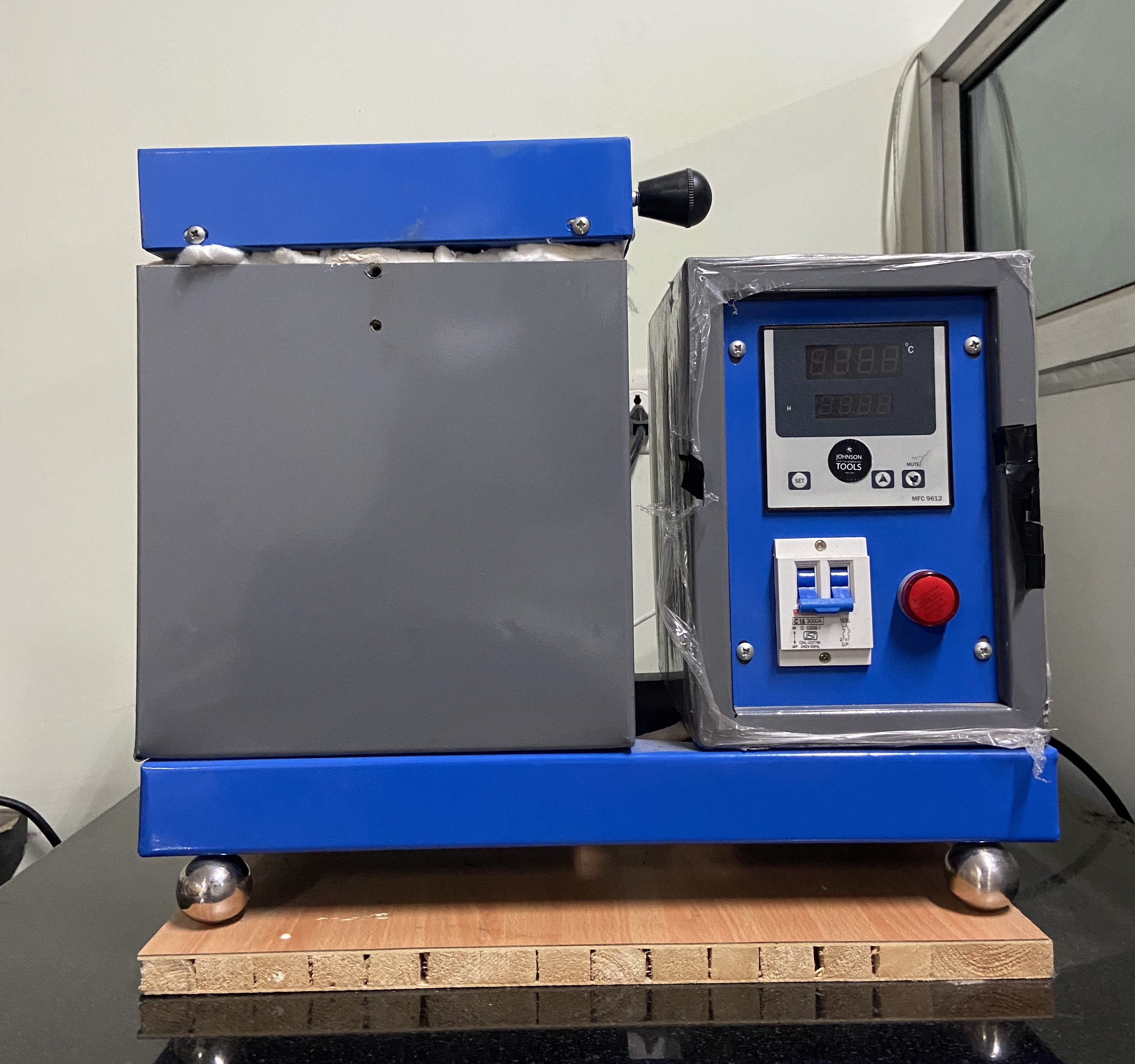

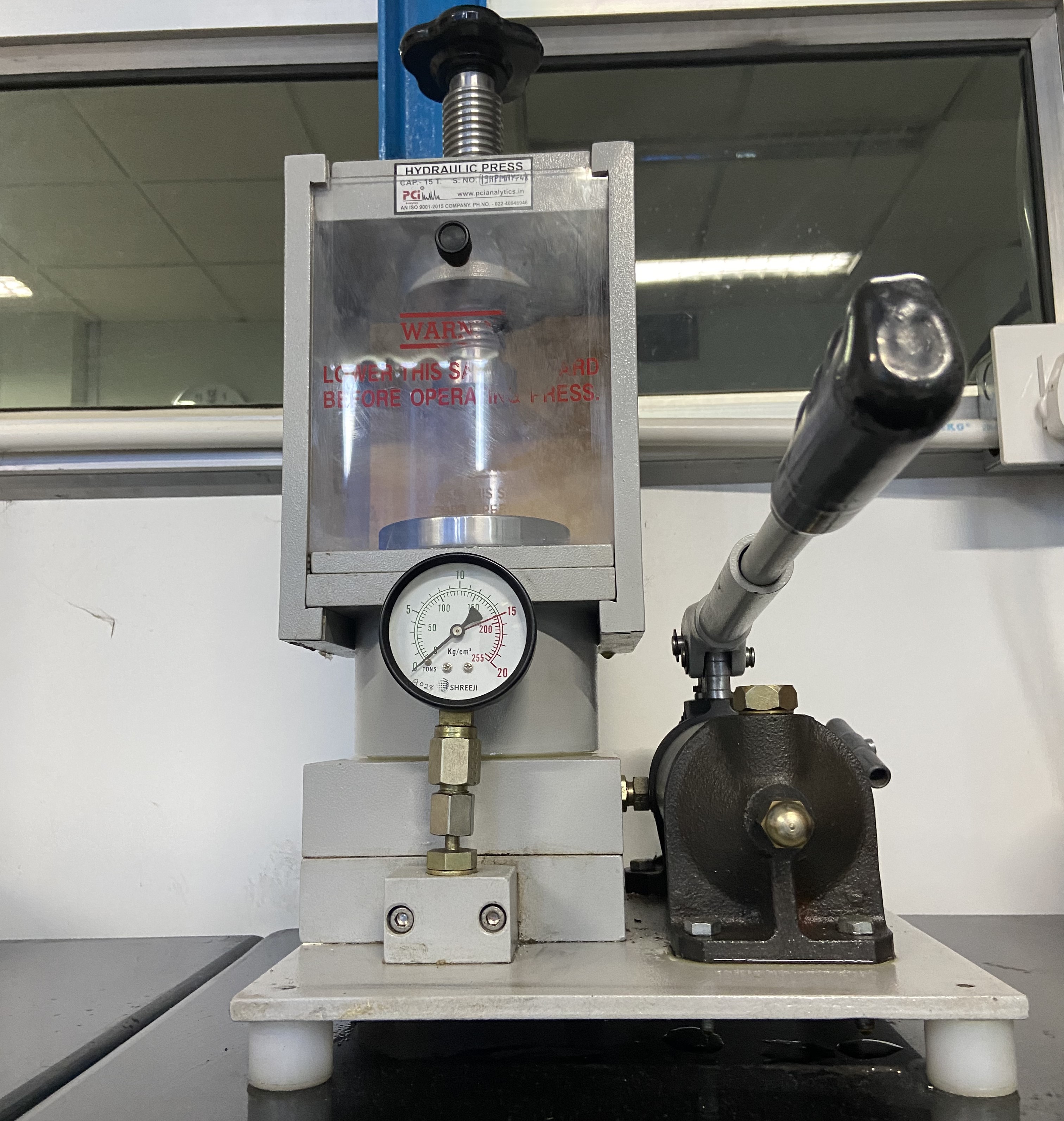

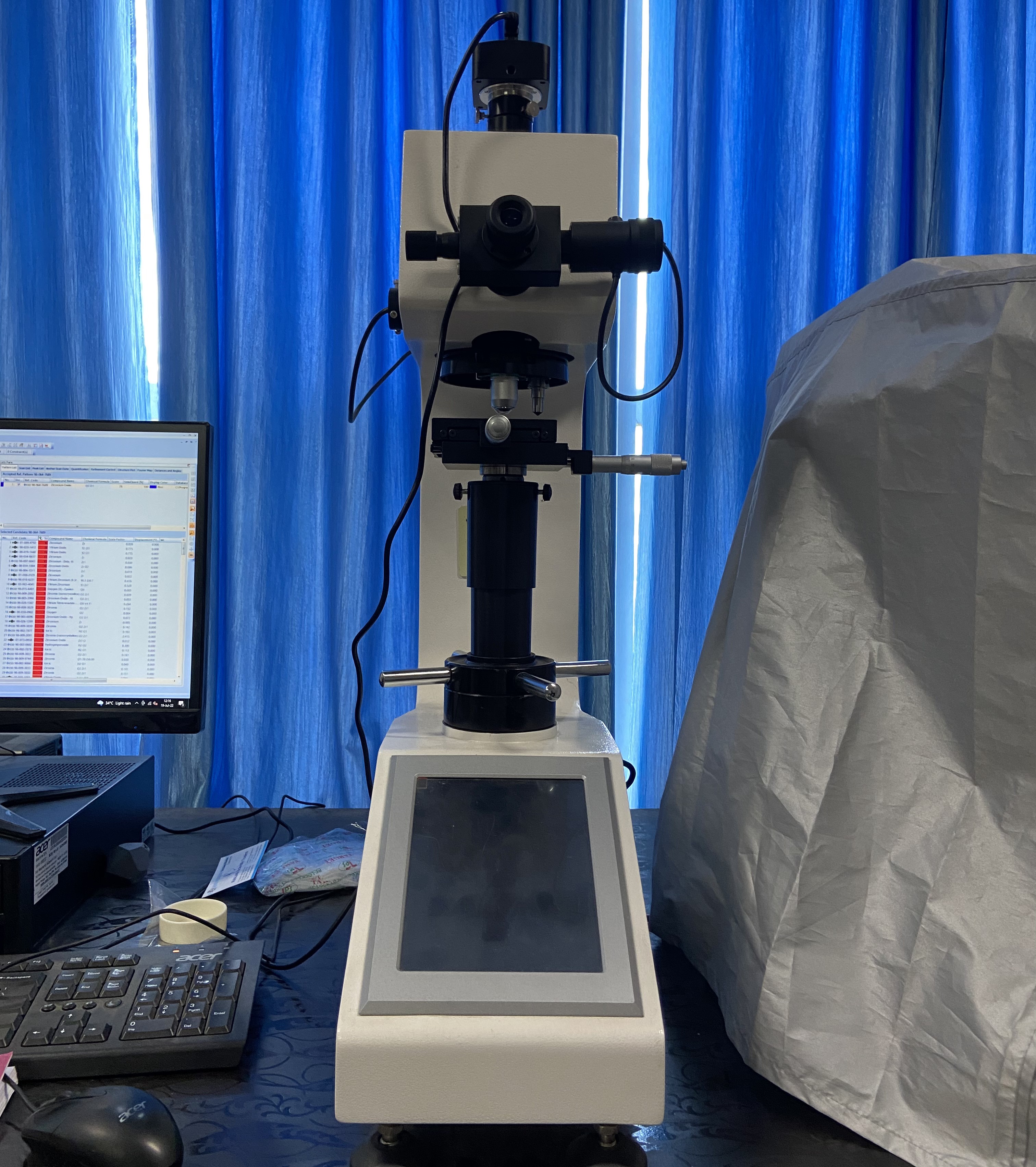

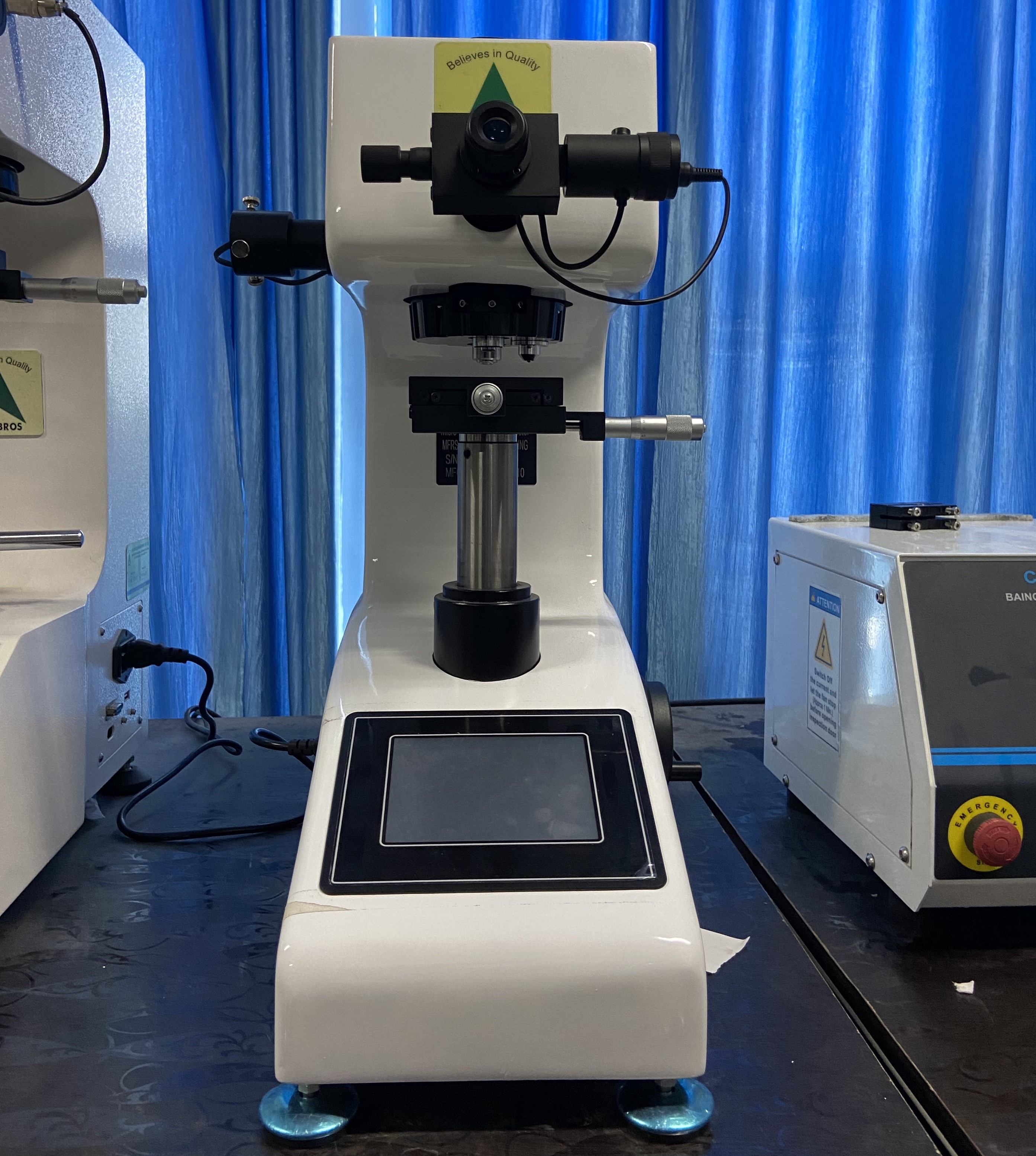

Research Facilities

National collaborators

International collaborators